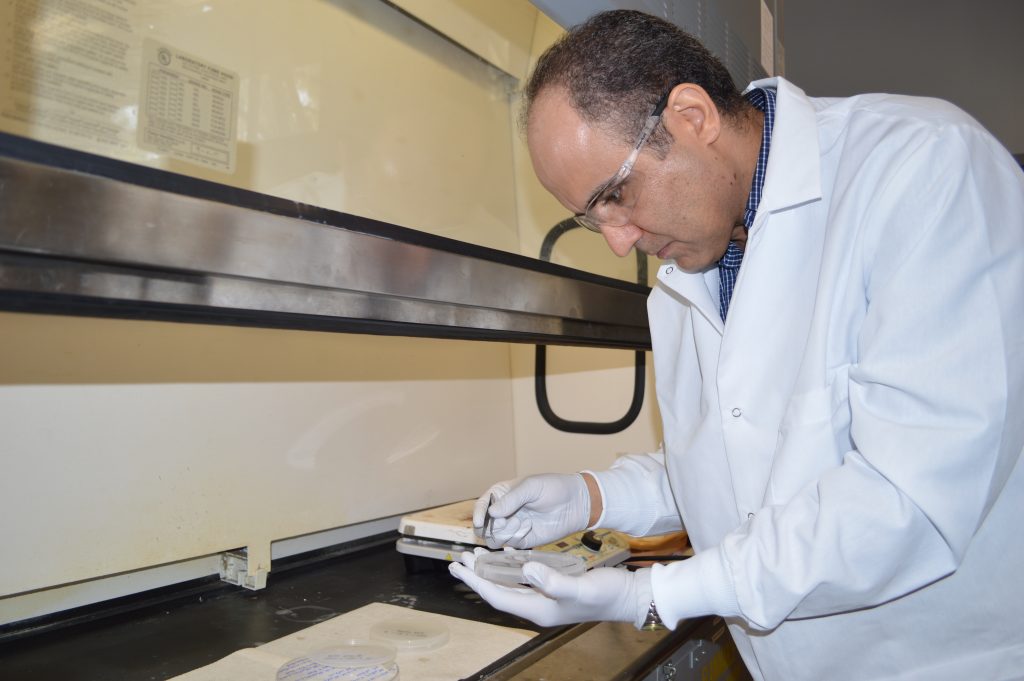

Saeed Moghaddam is an associate professor in the UF Herbert Wertheim College of Engineering’s Department of Mechanical and Aerospace Engineering.

You can’t always buy time, but you just might be able to engineer some.

For those with renal failure, the process of kidney dialysis is all too familiar: Three times a week, for a cumulative 12 hours, you sit in a chair and a machine does what your bean-shaped organs can’t—in this case, filter toxins out of your blood.

Although the treatment is an integral part of keeping those with advanced renal failure alive, patients’ quality of life leaves something to be desired. Dialysis of any kind is an unavoidable time sink, and one whose filtration systems have seen little change over the years.

But what if there was a way to make the process faster—and cheaper?

Saeed Moghaddam, Ph.D., an associate professor in UF’s Department of Mechanical and Aerospace Engineering, is developing a membrane with the potential to revolutionize this process by maximizing its efficiency.

In order for dialysis to eventually become something that patients may undergo from the comfort of their own home, Moghaddam identified two things that needed to change: the configuration of the membrane, and the material from which it was made.

“This membrane is based on simplicity,” Moghaddam said. “It is based on something that uses forces of physics, rather than brute force. I made it simple through better understanding and utilizing molecular and nanomaterials self-assembly processes.”

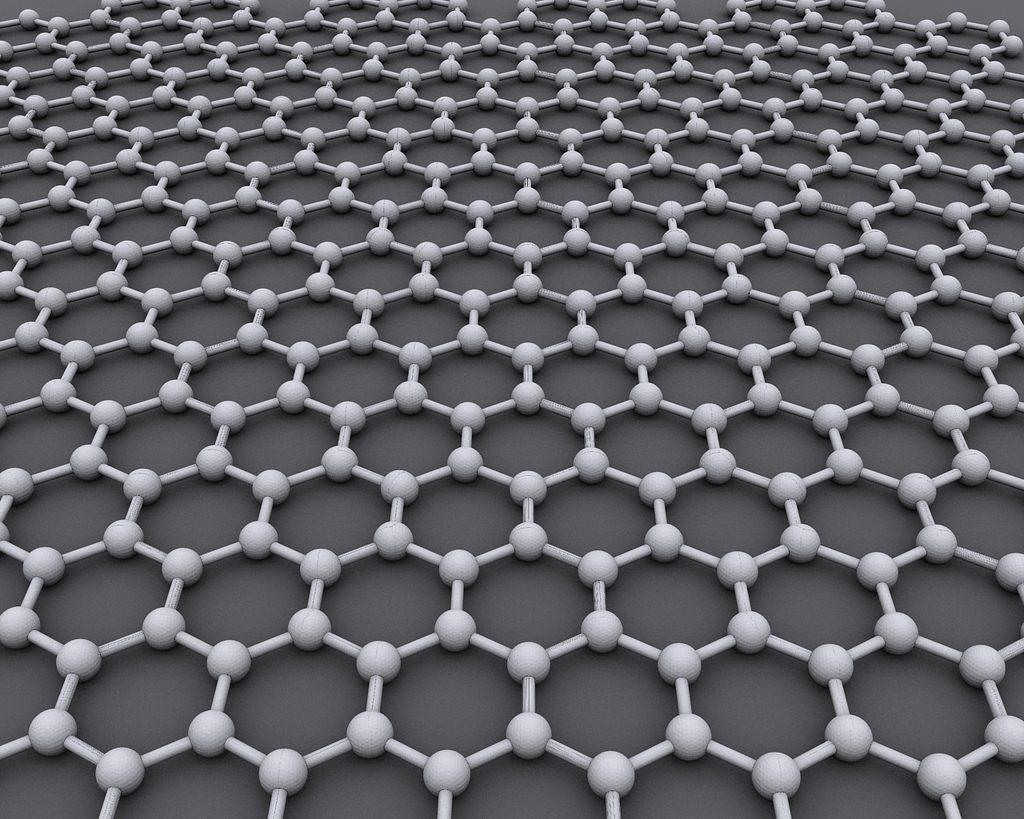

Moghaddam believes that new generation functional life support systems can be developed by advancing the science of materials interactions at both the molecular and nanoscale. In this case, the membrane is composed of two sheets of graphene, one of the thinnest possible existing molecular sieves. The two layers stagger the manmade pores in each sheet, lowering the chances of critical substances passing through.

As barbers joke that the secret to a good haircut is knowing what to leave behind, the same holds true for biomedical filtration.

“Graphene is a material that is comparatively quick and inexpensive to mass-produce, making this developing membrane a potentially uniquely positioned solution for the thousands on waiting lists for organ transplants.”

“The purpose is to be selective,” Moghaddam said. “You cannot keep losing red blood cells, albumin, or other valuable proteins through defects inherent to typical micro-and nanomanufacturing methods.”

When it comes to filtration, chemically modified graphene sheets are unparalleled in their adsorptive nature and selective permeability. Daniel Ornt, a clinical nephrologist and the Vice President of Health Sciences at the Rochester Institute of Technology, made sure that the project’s development and testing mimicked a clinical environment as closely as possible. For example, considering how patient experiences might be affected.

“The duration of treatment and size of the filter could be dramatically improved, cutting down on time spent at a clinic,” Ornt said. “It would also lend the dialysis process more speed and selectivity.”

But not only does the engineering behind the membrane speed up its intended purpose, it takes into account the production value and bigger goal.

“Both of us have the philosophy of looking for scalable nanomanufacturing that can be applied to significant problems our country and society faces,” said Thomas Gaborski, Ph.D the other PI on the NIH-backed project and associate professor of biomedical engineering at the Rochester Institute for Technology.

“We don’t just want to make a new nanomaterial discovery in our lab,” Gaborski said. “We want to translate this into a technology that can be useful beyond just the limited confines of our own research laboratories.”

Accordingly, graphene is a material that is comparatively quick and inexpensive to mass-produce, making this developing membrane a potentially uniquely positioned solution for the thousands on waiting lists for organ transplants.

“A liver or kidney transplant is always the best solution, but the supply is woefully inadequate around the world,” Gaborski said. “Technologies like this are necessary to help patients until that supply becomes available.”

Gaborski and Moghaddam’s project has received support from NIH and is just one of many recent interdisciplinary collaborations involving the University of Florida. Increasingly, research efforts at the university seek to explore the intersection between medicine and engineering, with innovative and promising results.

“By translating ideas from one discipline to another, I believe that we can have a really positive impact,” said David Hahn, chair of the Department of Mechanical and Aerospace Engineering. “It’s this interdisciplinary approach that we’re hoping to ingrain in our students—the idea that problem solving can be much more effective, and more efficient, if you consider a diversity in approaches.”