Gator engineers are shaping the future of things that are vital to society as we traverse the COVID-19 pandemic landscape: reliable testing, contact tracing methods, protection for healthcare workers, predictive models for efficient healthcare operations, and many other necessities. Take a glance at what we are doing and how you can help, and check back often for updates and to see new solutions we are creating.

Dr. Du Receives NSF RAPID Award for High-Frequency Data Collection for Human Mobility Prediction During COVID-19

Added June 29, 2020

PI: Eric Jing Du, UF Department of Civil & Coastal Engineering in the Engineering School of Sustainable Infrastructure & Environment (ESSIE); Co-PI: Ryan Qi Wang, Department of Civil and Environmental Engineering at Northeastern University

Eric Jing Du, Ph.D., an associate professor in the Department of Civil & Coastal Engineering within the Engineering School of Sustainable Infrastructure & Environment (ESSIE), in collaboration with Ryan Qi Wang, Ph.D., at Northeastern University, have received a Rapid Response Research Award from the National Science Foundation in support of their study on human social patterns post-pandemic. Using social media and high-frequency surveys through a newly created smartphone GPS-tracking app, they will learn and eventually predict human mobility behavior, which will improve the preparation of citizens and public agencies in future public health crises. The project is now at the stage of gathering data from roughly 500 individuals via social media and surveys over a 3-month period.

RAPID: Inexpensive, rapidly manufacturable respiratory monitor to provide safe emergency ventilation during the COVID-19 pandemic

Added June 25, 2020

PI: José Príncipe

Researchers in UF’s Department of Electrical & Computer Engineering are developing an inexpensive, portable, in-circuit respiratory monitor-ing technology that enables safe and effective care of multiple patients needing ventilation during a crisis when facilities and clinicians are stretched thin. The project utilizes novel signal processing at the sen-sors combined with custom algorithms to enable, for the first time, safe and effective ventilation of multiple patients with a single ventilator. The system can provide remote alarms and monitoring of any ventilat-ed patient using a low-cost smart sensor at the patient airway and a standard Android tablet outside the room.

ECE alumnus and longtime Príncipe associate Dr. Neil Euliano of Con-vergent Engineering also contributed to the project, providing assis-tance with the signal processing and aspects of the computer engineer-ing.

The monitor has been successfully prototyped; the ventilator-sharing concept has also been prototyped, but is not yet fully developed. Both devices can be rapidly cleared via FDA Emergency Use Authorization when completed.

Adaptive Sampling Strategies for COVID-19 Mass Testing

Added June 24, 2020

PI: Xiaochen Xian, Ph.D., UF Department of Industrial & Systems Engineering, Co PI’s Jaclyn Hall, Ph.D., UF College of Medicine – Health Outcomes & Biomedical Informatics, and Thomas Hladish, Ph.D., UF Department of Biology

Scientists in UF’s Department of Industrial and systems Engineering and collaborators from Health Outcomes and Biomedical Informatics and the Department of Biology are developing an adaptive sampling strategy for COVID-19 mass testing. The sampling strategy guides community testing using real-time analytics with the goal of elucidating patterns of virus transmission overtime in vulnerable communities and maximize the identification of cases while minimizing test resources. The algorithm is now at the stage of data-gathering from LifeSouth blood bank and simulation.

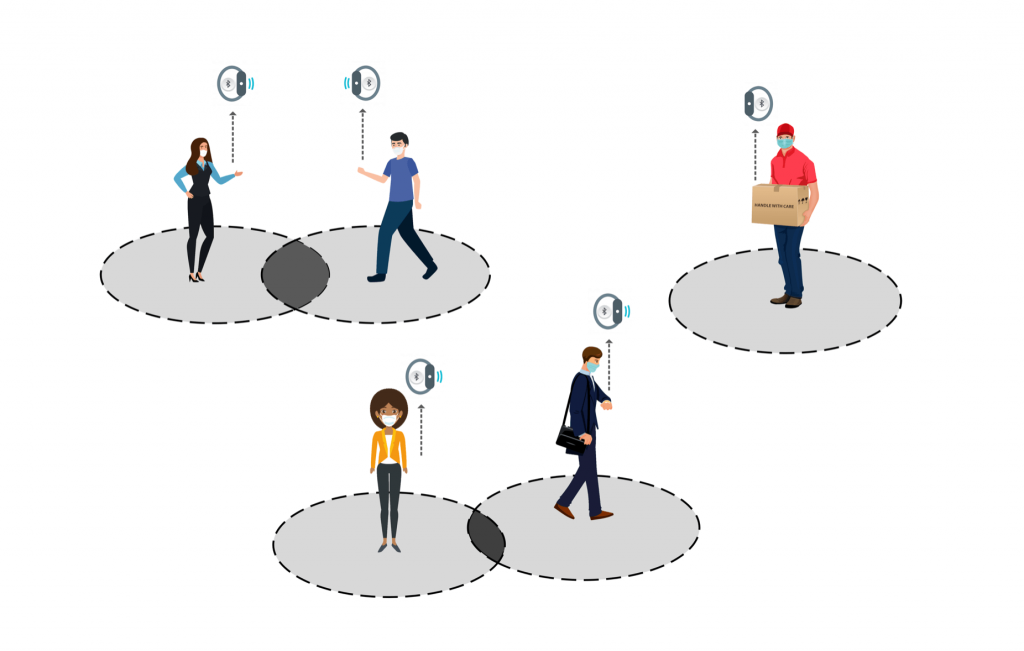

Ultra-Low Cost Social Distancing Band

Added June 15, 2020

PI: Yier Jin, Ph.D., Director of Academic Programs for the Warren B. Nelms Institute for the Connected World and Associate Professor and IoT Term Professor, Department of Electrical & Computer Engineering, Co-PIs: My Thai, Ph.D., Associate Director of the Warren B. Nelms Institute for the Connected World and UF Research Foundation Professor, Department of Computer & Information Science & Engineering; and Ahmed Helmy, Professor, Department of Computer & Information Science & Engineering

Scientists in UF’s Warren B. Nelms Institute for the Connected World are developing an affordable wearable device that indicates appropriate social distancing. The researchers’ approach utilizes Bluetooth Low Energy (BLE) technology in a wearable wrist band. BLE signal strength (RSSI) and transmission power level (TX_power) are used by novel distance estimation and classification algorithms, to notify users if they are within a specified distance range (e.g., less than 6ft) of another person. The detected signals can also be stored locally on the wearable device for:- 1) preserving privacy and 2) estimating exposure risks as needed. This project addresses the issue of social distancing in traditionally crowded settings, such as K-12 schools, and universities, among others. The basic work of designing the algorithms for measuring distance between people and adapting the software into a wearable band has been completed, and the project is now at the stage of gathering data to evaluate the band’s accuracy in a group of people.

Assistant professor develops a rapid point-of-care detection technology for SARS-CoV-2

Piyush Jain, Ph.D., an assistant professor in the Department of Chemical Engineering and a member of the UF Health Cancer Center, and Long Nguyen, a Ph.D. student, have developed a CRISPR-based, paper-based, rapid detection technology that can identify SARS-CoV-2 cDNA in as little as 5-10 minutes or SARS-CoV-2 RNA in as low as 30-60 minutes without the need of expensive equipment. They want to utilize this technology to create an inexpensive at-home Coronavirus test kit, similar to pregnancy test strips.

UF faculty receive NSF EAGER award to help hospitals combat covid-19

Industrial & Systems Engineering Professor Yongpei Guan, Ph.D. and Assistant Professor Xiang Zhong, Ph.D., have received an Early Concept Grant for Exploratory Research from the National Science Foundation in support of their study on data-driven Susceptible-Exposed-Infected-Recovered-Infected (SEIRI) modeling and risk averse sequential planning for patient beds, staffing and personal protective equipment (PPE) in hospitals to combat the Coronavirus Disease 2019 (COVID-19).

COVID Hospital Resource Capacity Planning Using Discrete-Event and Agent-Based Simulation Modeling

PI: Michele Alvarado, Ph.D., UF Department of Chemical Engineering, Co-PI, Patrick Tighe, MD, UF Anesthesiology

Engineers in UF’s Department of Industrial and Systems Engineering and collaborators from the Department of Anesthesiology are developing a discrete-event and agent-based simulation for modeling COVID-19 hospital facility management. These decision tools have the potential impact to allow advanced mitigation planning for elective and urgent surgical procedures including trauma, stroke, and chest pain under extreme resource constraints caused by the COVID-19 pandemic. The simulation models are now at the stage of model enhancement and validation for semi-automated decision-making.

Detecting hazardous actions such as coughing, sneezing, food sabotaging, and incorrect social distancing in retail settings during COVID-19 pandemic and beyond

PI: Dr. Read Hayes, Director, Loss Prevention Research Council, Co-PIs: Eakta Jain, Ph.D., Department of Computer & Information Science & Engineering, and Boyi Hu, Ph.D., Department of Industrial and Systems Engineering

Scientists in UF’s Department of Computer & Information Science & Engineering and collaborators from the UF Department of Industrial and Systems Engineering and Loss Prevention Research Council are developing a dataset of hazardous actions, such as coughing, sneezing, food sabotaging, and incorrect social distancing, for the purpose of conducting a Kaggle contest and a UF hack-a-thon to spur algorithms that can be used for automatic flagging of these actions. This dataset and challenge have the potential to make essential activities, such as grocery and pharmacy visits, safer for shoppers and employees and could have a wider applicability for controlling the spread of other diseases such as the influenza virus. This dataset and challenge will create an opportunity to innovate and benchmark new algorithms focused on pandemic-related actions. The project is now at the stage of developing a plan and applying for funding from the UF Clinical and Translational Science Institute.

Surveillance of Airborne SARS-CoV-2 Virus for Personnel Protection against COVID-19

PI: CY Wu, UF Department of Environmental Engineering at the Engineering School of Sustainable Infrastructure & Environment (ESSIE), Co-PI: Hugh Fan, UF Department of Mechanical and Aerospace Engineering

Engineers in the UF Department of Environmental Engineering Sciences at the Engineering School of Sustainable Infrastructure & Environment (ESSIE) are developing a novel virus aerosol sampler for a non-invasive technology for COVID-19 detection. The device efficiently collects the airborne virus, the information of which enables healthcare providers pinpoint risk areas and identify measures for improvement. The application has the potential of applying beyond the testing areas, and eventually, general public areas (e.g. airports, subways, government buildings, shopping centers) will be able to adopt this powerful device in order to detect airborne pathogenic viruses early on and effectively mitigate their spread. Dr. Chang-Yu Wu and his team are deploying this device in various locations to gather samples, which we should receive in a few weeks.

Sensors to Detect Bio-Components

PI: Fan Ren, UF Department of Chemical Engineering and Stephen Pearton, UF Department of Materials Science and Engineering

Scientists at the Departments of Chemical Engineering and Materials Science and Engineering are developing a sensor platform for a low-cost, disposable, fast-response technology for COVID-19 detection using test strips similar to glucose test strips. The sensor potentially has a response-time for less than 1 minute. The detected signals intend to be developed as digital electrical signal, which does not need trained technicians to operate the detection. The detected signal can be automatically recorded.

UF Engineers research compact portable unit to disinfect SARS Cov-2 contaminated surfaces

PI: Roy, Subrata, Department of Mechanical and Aerospace Engineering

Scientists in UF’s Department of Mechanical & Aerospace Engineering are developing a novel solution to disinfect SARS CoV-2-contaminated surfaces using Dielectric Barrier Discharge (DBD) plasma reactors. Their research will create a safe, energy-efficient, easy-to-use, compact portable disinfection unit. DBD technology acts as a powerful reusable disinfection system for surfaces and objects, including masks, gloves, suits, equipment, medical supplies, and personal effects. The plasma-based decontamination technology has already been proven against a wide range of bacteria and viruses and thus shows promise for inactivation and inhibition of SARS CoV-2. The research is currently submitted as an initiative for funding where the next steps will include testing at UF’s Emerging Pathogens Institute. Dr. Subrata Roy’s engineering team and collaborators from the College of Public Health and Health Professions will test the decontamination technology, and initial results will be available in approximately three months. With successful test results, the portable disinfection units can quickly be made available to protect frontline healthcare personnel in crowded medical and laboratory facilities where rapid disinfection of personal protection equipment is essential.

TRIDENT: A trimodal sensory system for detecting onset of an infection

PI: Soumyajit Mandal, Ph.D., UF Warren B. Nelms Institute for the Connected World, Co-PI: Forrest Masters, Ph.D., UF Engineering School of Sustainable Infrastructure & Environment, Yier Jin, Ph.D., Sandip Ray, Ph.D., Swarup Bhunia, Warren B. Nelms Institute for the Connected World; Nikolaus Gravenstein, M.D. UF Anesthesiology

Engineering researchers in UF’s Warren B. Nelms Institute for the Connected World are developing TRIDENT, a tri-modal sensory system for detecting onset of an infection such as COVID-19. TRIDENT is built on an Internet of Things (IoT) infrastructure that utilizes a three-pronged suite of connected sensors and devices: multi-modal sensors, interactive edge devices, and secure cloud-based software. These components work in conjunction with one another to provide real-time alerts to individuals and guidelines for precautionary measures while constantly assessing the risk of contracting the virus or spreading it by alerting users when they are unintentionally violated. The system uses readily available components, such as mobile phones, making it very accessible and affordable and enabling anyone at risk to easily integrate it into their home/work environments. TRIDENT can also monitor and provide informative predictions to assess the condition of patients who are already quarantined or hospitalized and then model their disease progression.

Please check back regularly, as we will post additional information and new research projects whenever information is available.