Click to Enter the Poster Zoom Room: Poster 06 Zoom Link or Return to Poster Session 1 List

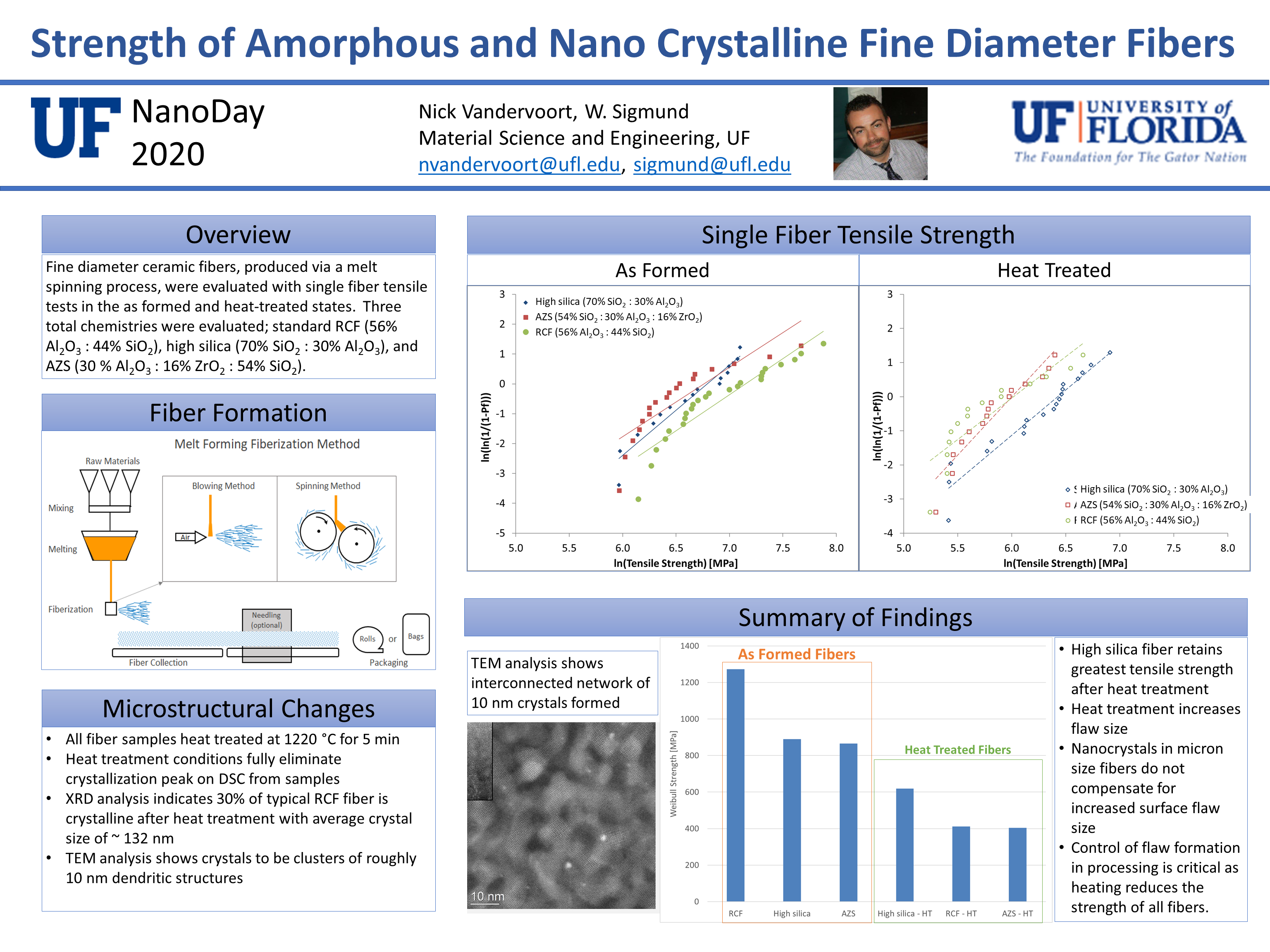

Strength of amorphous and nano crystalline fine diameter fibers Nick Vandervoort (LinkedIn) Authors: Nick Vandervoort and Wolfgang Sigmund Faculty Mentor: Wolfgang Sigmund, PhD College: College of Engineering Department: Material Science Engineering |

|

AbstractFine diameter ceramic fibers, produced via a melt spinning process, were evaluated with single fiber tensile tests and fiber mat compression tests in the as formed and heat-treated states. Three total chemistries were evaluated; standard RCF (56% Al2O3 : 44% SiO2), high silica (70% SiO2 : 30% Al2O3), and AZS (30 % Al2O3 : 16% ZrO2 : 54% SiO2). The heat treatment caused the RCF fibers to form 132 +/- 8 nm clusters of roughly 10 nm dendritic mullite crystals from their previously amorphous structure. The single filament tensile strength data was characterized using Weibull statistics. Of the as formed fibers, the RCF fiber provided the highest Weibull strength of 1272 MPa. After heat treatment, the high silica fiber was found to have both the smallest reduction in Weibull strength, 30%, and highest Weibull strength of 618 MPa. With the highest tensile strength of the heat-treated fibers, it was expected that the high silica fiber would measure the highest fiber mat compression. Surprisingly, the high silica fiber measured significantly lower compression than the RCF fiber, despite having significantly higher Weibull strength. This indicates that the nanocrystals contribute to the improved mat compression performance possibly in a toughening mechanism as the higher silica formulation s expected to retain a greater amount of amorphous structure.

|

|

|

|

|

Poster Pitch |